Outdoor Lamp Pole Street Light Pole Single Double Arm

DOWNLOAD

RESOURCES

Description

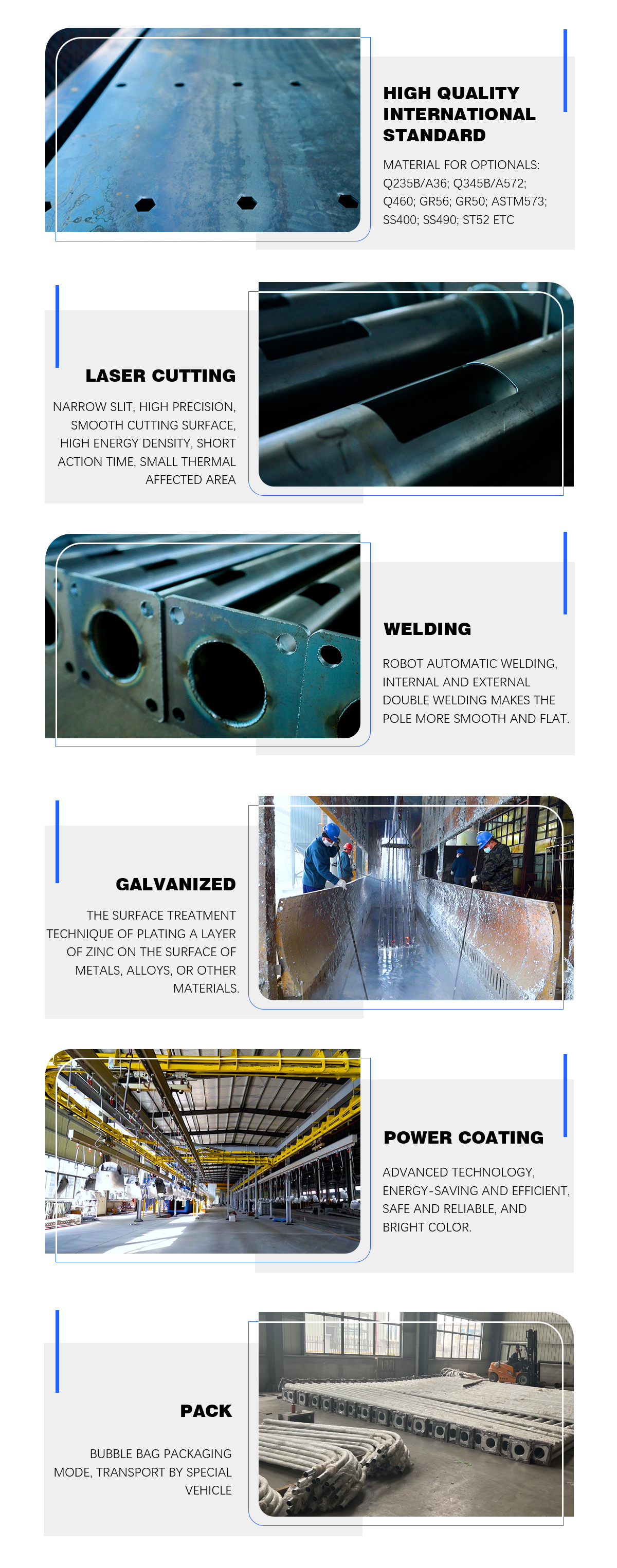

The street light pole is mainly made of high-quality Q235 steel by bending.

The welding method of the street lamp pole is automatic sub-arc welding.

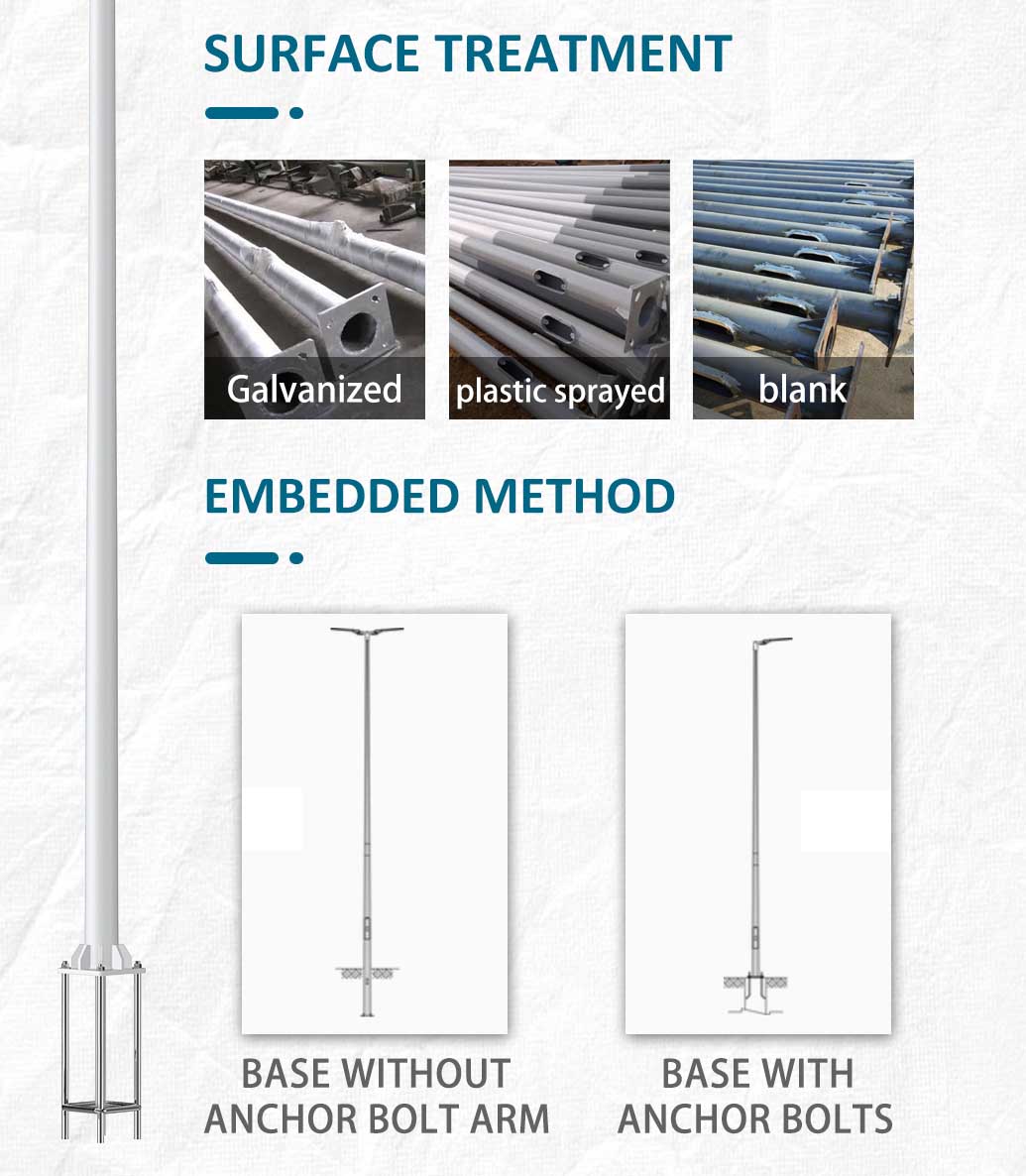

Street light poles are hot-dip galvanized anti-corrosion treatment.

The street light pole should be sprayed with high-quality outdoor pure polyester plastic powder, and the color can be freely selected by customers.

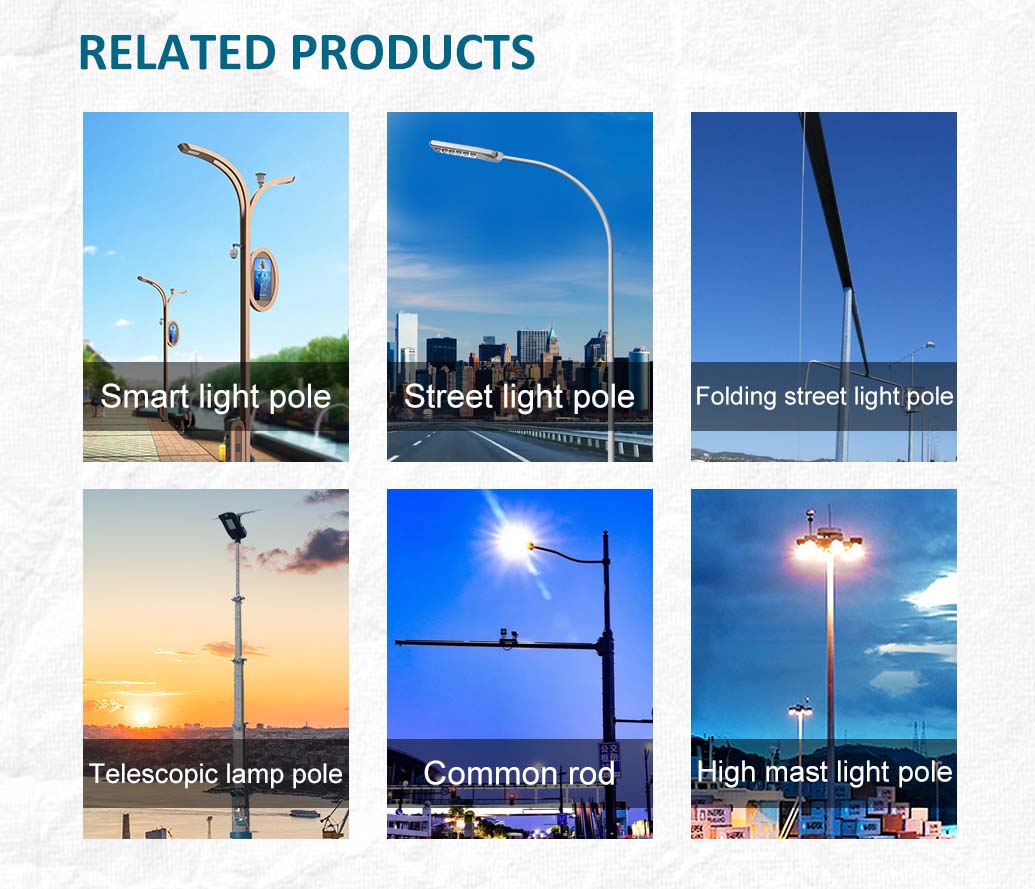

With the development of the times, the application of street light poles is also constantly changing. The first generation of street light poles is only a pole that supports the light source. Later, after solar street lights were added to the market, we took into account the windward area of the solar panel and the wind resistance coefficient. Wait, I have seen rigorous calculations and tried again and again. Solar street lights are now a very mature product in the street light market. Later, there are too many poles on the road. We integrate the nearby poles, such as signal lights and street lights. , signs and street lights have become the current common pole, making the road clean and tidy. Street lights have become one of the road facilities with the widest coverage. In the future, 5g base stations will also be integrated with street lights to make the signal coverage wider. It is also an important infrastructure for future driverless technology.

Our company has been working for the street lighting business for nearly 20 years. In the future, we will continue to work hard for urban infrastructure and road lighting business to improve the living environment and promote the development of the times.

Effect Pictures

Manufacturing Process

Our Certifications

Our Exhibition

Why choose our HDG pole?

1. Corrosion resistance:

Our hot-dip galvanized poles have strong corrosion resistance and are suitable for outdoor applications under various weather conditions.

2. Long service life:

Our hot-dip galvanizing process forms a durable coating, which can extend the service life of the light pole and reduce the need for frequent replacement.

3. Low maintenance:

Our HDG poles require minimal maintenance, saving time and resources in the long run.

4. Beautiful:

The uniform and shiny surface of our HDG light poles can enhance the visual appeal of outdoor spaces.

5. Environmental sustainability:

HDG is a sustainable coating method that provides long-term protection for our light poles and reduces the environmental impact of frequent replacement.

6. Cost-Effectiveness:

Our HDG poles have a long life and low maintenance requirements can lead to cost savings over time.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top