Outdoor Hot Dip Galvanized Driveway Light Pole

DOWNLOAD

RESOURCES

Description

Outdoor Hot Dip Galvanized Driveway Light Pole is made of high-quality Q235 steel pipe, with a smooth and beautiful surface; The main pole diameter is made of circular tubes with corresponding diameters according to the height of the lamp post; After welding and forming, the surface is polished and hot-dip galvanized, followed by high-temperature spray coating; The appearance of the pole can be customized with spray paint colors, including regular white, color, gray, or blue+white.

Technical Data

| Product Name | Outdoor Hot Dip Galvanized Driveway Light Pole | ||||||

| Material | Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 | ||||||

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | ||||||

| Minimum yield strength | 285Mpa | ||||||

| Max ultimate tensile strength | 415Mpa | ||||||

| Anti-corrosion performance | Class II | ||||||

| Against earthquake grade | 10 | ||||||

| Color | Customized | ||||||

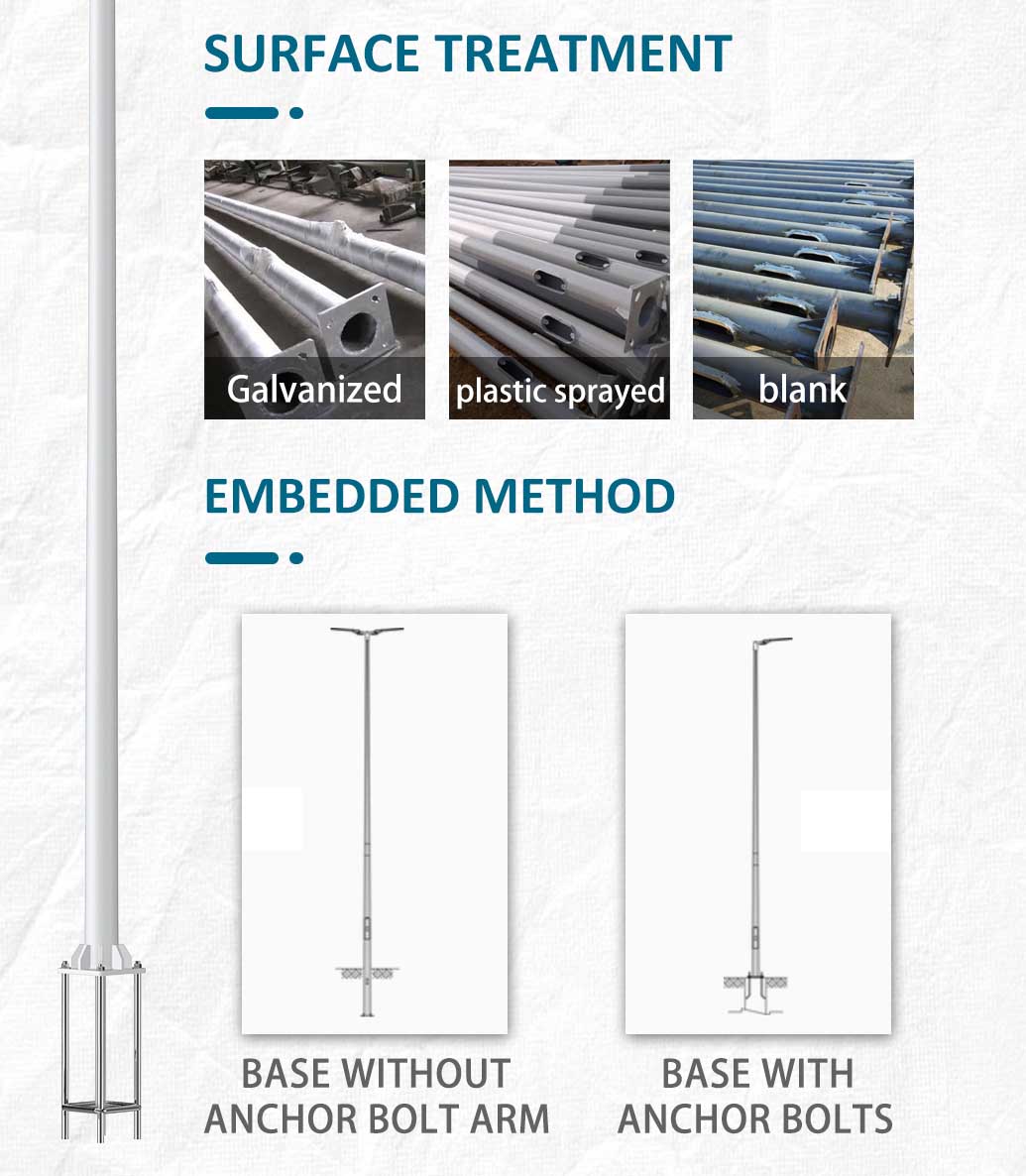

| Surface treatment | Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II | ||||||

| Shape Type | Conical pole, Octagonal pole,Square pole, Diameter pole | ||||||

| Arm Type | Customized: single arm,double arms,triple arms,four arms | ||||||

| Stiffener | With big size to strength the pole to resist the wind | ||||||

| Powder coating | Thickness of powder coatingis 60-100um.Pure polyester plastic powder coating is stable, and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). | ||||||

| Wind Resistance | According to local weather condition, General design strength of wind resistance is ≥150KM/H | ||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | ||||||

| Hot-Dip Galvanized | Thickness of hot-galvanized is 60-100um.Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of pole is more than 25 years, and the galvanized surface is smooth and with the same color. Flake peeling hasn't been seen after maul test. | ||||||

| Anchor bolts | Optional | ||||||

| Material | Aluminium,SS304 is available | ||||||

| Passivation | Available | ||||||

Manufacturing Process

Features

Corrosion resistance

The hot-dip galvanizing process forms a strong zinc coating by dipping the steel pole into molten zinc, providing excellent anti-corrosion protection and extending the service life of the light pole.

Weather resistance

This driveway light pole can withstand various weather conditions, including rain, snow, wind and sunlight, and is suitable for use in outdoor environments.

Strength and stability

The use of high-strength steel ensures the stability of the driveway light pole under the action of wind and other external forces, making it suitable for installation in driveways and other areas with heavy traffic.

Aesthetics

Hot-dip galvanized driveway light poles usually have a smooth surface and modern appearance, which can blend harmoniously with the surrounding environment and enhance the overall aesthetics.

Easy to install

The design usually takes into account the convenience of installation, and is equipped with standard mounting accessories for quick installation and maintenance.

Multiple heights and specifications

Driveway light poles of different heights and specifications can be provided according to demand to adapt to different lighting needs and environments.

Project Presentation

Our Exhibition

Every year, our company actively participates in multiple international exhibitions to showcase our light pole products.

Our driveway light pole products have successfully entered many countries such as the Philippines, Thailand, Vietnam, Malaysia, and Dubai. The diversity of these markets provides us with a wealth of experience that allows us to better adapt to the needs of different regions. For example, in countries with tropical climates, our light poles are designed with high temperature and humid environments in mind, ensuring their durability and stability. In areas with rapid urbanization, our light poles focus on the combination of aesthetics and functionality to enhance the overall image of the city.

Through interactions with customers, we are able to collect valuable market feedback, which provides guidance for our subsequent product development and market strategies. In addition, the exhibition is also a good opportunity for us to showcase our corporate culture and sustainable development concepts, and convey our commitment to environmental protection and social responsibility to customers.

Looking to the future, we plan to continue to expand the coverage of the international market, explore new cooperation opportunities, and continuously improve product quality and service levels to meet the needs of global customers. Through these efforts, we hope to further consolidate our position in the international market and promote the company's continued development.

Our Certifications

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top