Galvanized light poles are an important part of urban infrastructure, providing lighting for streets, parks, and public places. As a leading galvanized light pole supplier, Tianxiang is committed to providing high-quality products that meet the diverse needs of customers. In this article, we will explore the manufacturing process of galvanized light poles, highlighting the importance of galvanizing and the benefits it brings.

Understanding Galvanizing

Galvanizing is a process that coats steel or iron with a layer of zinc to prevent corrosion. This protective coating is critical for light poles, which are often exposed to harsh weather conditions, including rain, snow, and extreme temperatures. Not only does the galvanizing process extend the life of light poles, it also reduces maintenance costs, making it an affordable option for municipalities and businesses.

Manufacturing process of galvanized light pole

The production of galvanized light poles involves several key steps, each of which affects the durability and performance of the final product. Here is a detailed description of how galvanized light poles are made:

1. Material selection

The first step in manufacturing galvanized light poles is to select the right material. High-quality steel is usually used because of its strength and durability. Steel is sourced from reputable suppliers to ensure compliance with industry standards. At Tianxiang, we prioritize the quality of raw materials to ensure the longevity of our galvanized light poles.

2. Cutting and shaping

Once the steel is selected, it is cut to the desired length and shape. This process may involve the use of advanced machinery to ensure precision and consistency. Light poles can be designed in a variety of heights and diameters, depending on their intended use. For example, a street light pole may be taller than a light pole used in a park or residential area.

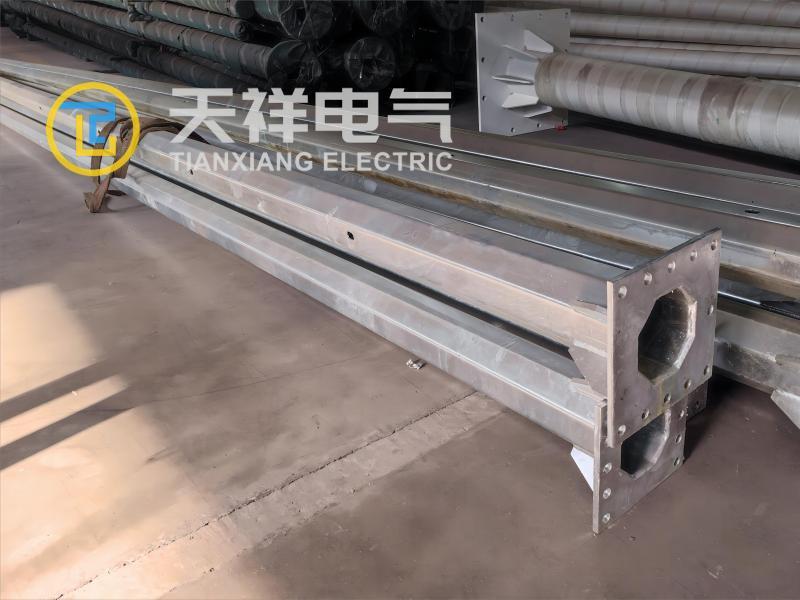

3. Welding and assembly

After cutting, the steel components are welded together to form the structure of the light pole. This step is critical as it ensures that the light pole is strong and can withstand environmental stress. Tianxiang’s skilled welders use advanced technology to create strong joints that enhance the overall integrity of the light pole.

4. Surface preparation

Prior to galvanizing, utility poles undergo a surface preparation process to remove any contaminants such as rust, oil or dirt. This step is critical to ensure that the zinc coating adheres properly to the steel. The surface preparation process typically involves cleaning the poles through methods such as grit blasting or chemical cleaning.

5. Galvanizing

At the heart of the manufacturing process is galvanizing. The prepared poles are immersed in a bath of molten zinc at a temperature of approximately 450 degrees Celsius. This process causes the zinc to react with the iron in the steel, forming a series of zinc-iron alloy layers that provide excellent corrosion resistance. The poles are then removed from the bath and cooled, resulting in a durable protective coating.

6. Quality control

At Tianxiang, we take quality control very seriously. After galvanizing, each pole is rigorously inspected to ensure it meets our high standards. This includes checking the thickness of the zinc coating, inspecting the welds, and ensuring the pole is free of defects. Our commitment to quality ensures that our galvanized poles are reliable and long-lasting.

7. Finishing touches

Once the poles have passed quality control, they may undergo additional finishing touches such as painting or adding decorative elements. While galvanized coatings provide excellent protection, some customers may prefer a specific color or finish to suit their aesthetic requirements. At Tianxiang, we offer custom options to meet our customers’ unique needs.

8. Packaging and delivery

Finally, the finished galvanized light poles are carefully packed for delivery. We ensure that they are securely packaged to prevent damage during transportation. As a reputable galvanized light pole supplier, Tianxiang is committed to timely delivery, ensuring that our customers receive their orders when they need them.

Benefits of galvanized light poles

Galvanized light poles offer many advantages that make them a popular choice for a variety of applications:

Corrosion Resistant: The zinc coating protects the steel from rust and corrosion, extending the life of the pole.

Low Maintenance: Galvanized poles require minimal maintenance, reducing long-term costs for municipalities and businesses.

Durability: The sturdy construction of the galvanized light poles ensures they can withstand harsh weather conditions and frequent use.

Aesthetic Appeal: Galvanized light poles have a variety of customization options to enhance the visual appeal of public spaces.

In conclusion

In summary, the manufacturing process of galvanized light poles involves several key steps, from material selection to galvanizing and quality control. As a leading galvanized light pole supplier, Tianxiang is proud to provide high-quality products that meet customer needs. If you are looking for durable and reliable galvanized light poles, we invite you to contact us for a quote. Our team is ready to assist you in finding the perfect solution for your lighting needs.

Post time: Dec-26-2024