LED Street Light Pole with Factory Price

DOWNLOAD

RESOURCES

Description

The street light pole is mainly made of high-quality Q235 steel by bending.

The welding method of the street lamp pole is automatic sub-arc welding.

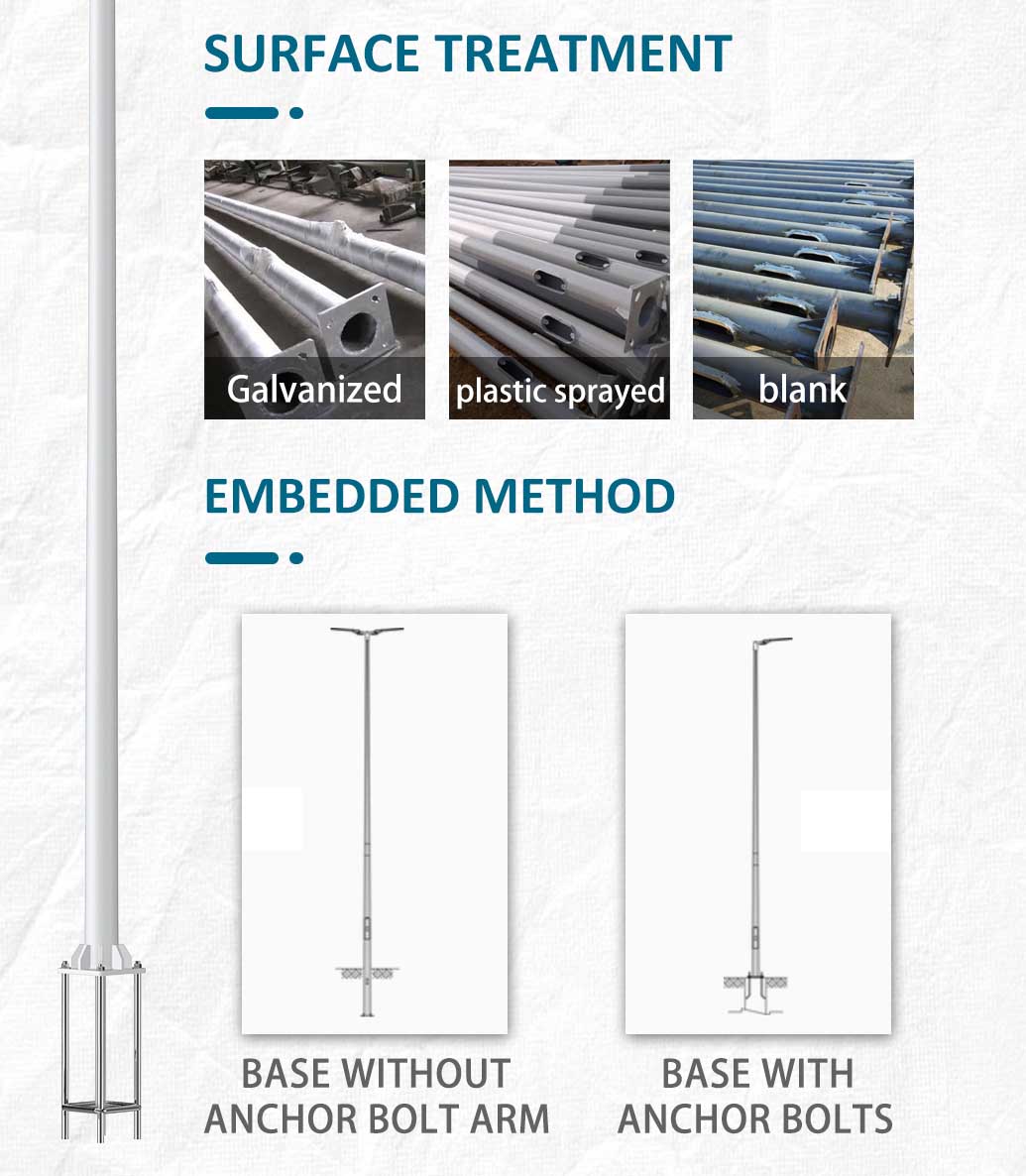

Street light poles are hot-dip galvanized anti-corrosion treatment.

The street light pole should be sprayed with high-quality outdoor pure polyester plastic powder, and the color can be freely selected by customers.

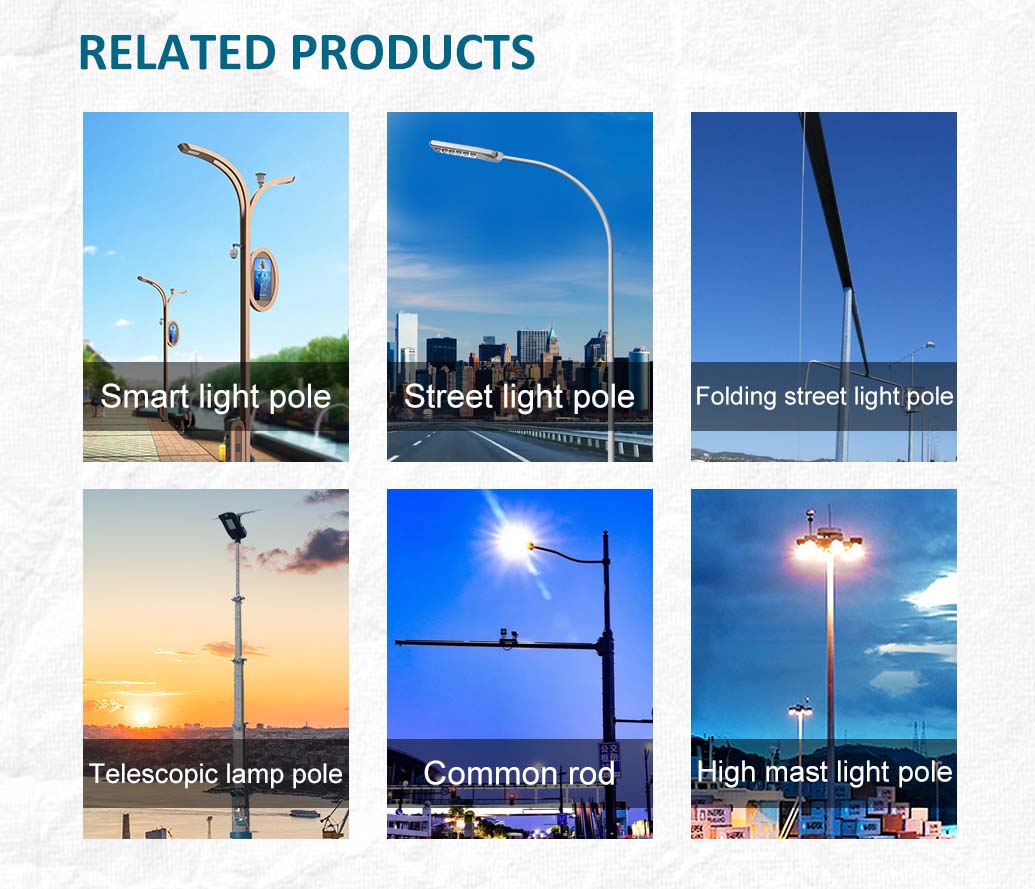

With the development of the times, the application of street light poles is also constantly changing. The first generation of street light poles is only a pole that supports the light source. Later, after solar street lights were added to the market, we took into account the windward area of the solar panel and the wind resistance coefficient. Wait, I have seen rigorous calculations and tried again and again. Solar street lights are now a very mature product in the street light market. Later, there are too many poles on the road. We integrate the nearby poles, such as signal lights and street lights. , signs and street lights have become the current common pole, making the road clean and tidy. Street lights have become one of the road facilities with the widest coverage. In the future, 5g base stations will also be integrated with street lights to make the signal coverage wider. It is also an important infrastructure for future driverless technology.

Our company has been working for the street lighting business for nearly 20 years. In the future, we will continue to work hard for urban infrastructure and road lighting business to improve the living environment and promote the development of the times.

Technical Data

| Product Name | LED Street Light Pole with Factory Price | ||||||

| Material | Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 | ||||||

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | ||||||

| Minimum yield strength | 285Mpa | ||||||

| Max ultimate tensile strength | 415Mpa | ||||||

| Anti-corrosion performance | Class II | ||||||

| Against earthquake grade | 10 | ||||||

| Color | Customized | ||||||

| Surface treatment | Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II | ||||||

| Shape Type | Conical pole, Octagonal pole,Square pole, Diameter pole | ||||||

| Arm Type | Customized: single arm,double arms,triple arms,four arms | ||||||

| Stiffener | With big size to strength the pole to resist the wind | ||||||

| Powder coating | Thickness of powder coating is 60-100um. Pure polyester plastic powder coating is stable, and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). | ||||||

| Wind Resistance | According to local weather condition, General design strength of wind resistance is ≥150KM/H | ||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | ||||||

| Hot-Dip Galvanized | Thickness of hot-galvanized is 60-100um. Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of pole is more than 25 years, and the galvanized surface is smooth and with the same color. Flake peeling hasn't been seen after maul test. | ||||||

| Anchor bolts | Optional | ||||||

| Material | Aluminium,SS304 is available | ||||||

| Passivation | Available | ||||||

Manufacturing Process

Project Presentation

Our Exhibition

Our Certifications

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top