Hot Sale 4m-12m Cast Bent Light Pole

DOWNLOAD

RESOURCES

Technical Data

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | ||||||

| Minimum yield strength | 285Mpa | ||||||

| Max ultimate tensile strength | 415Mpa | ||||||

| Anti-corrosion performance | Class II | ||||||

| Against earthquake grade | 10 | ||||||

| Color | Customized | ||||||

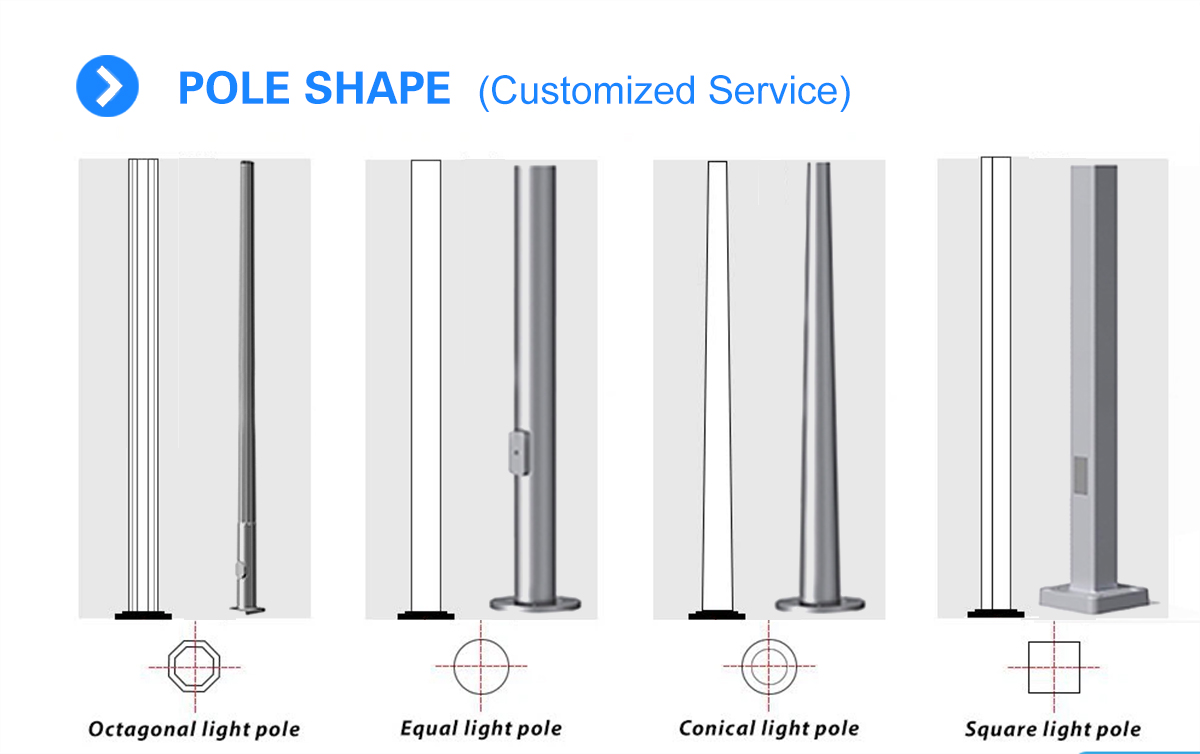

| Shape Type | Conical pole, Octagonal pole, Square pole, Diameter pole | ||||||

| Arm Type | Customized: single arm, double arms, triple arms, four arms | ||||||

| Stiffener | With a big size to strengthen the pole to resist the wind | ||||||

| Powder coating | Thickness of powder coating is 60-100um. Pure polyester plastic powder coating is stable and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). | ||||||

| Wind Resistance | According to local weather conditions, the General design strength of wind resistance is ≥150KM/H | ||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | ||||||

| Anchor bolts | Optional | ||||||

| Material | Aluminium | ||||||

| Passivation | Available | ||||||

Steps for Bending Light Poles

Bending light poles can be a complex task that requires specialized equipment and expertise. Here are the general steps professionals follow when bending light poles:

Assess the Site:

Before starting any work, it is important to assess the site where the poles will be installed. Consider factors such as terrain, proximity to utility lines, and any potential obstructions.

Gather Materials and Equipment:

Gather all materials and equipment needed for the job, including light poles, bending equipment (such as a hydraulic bender), leveling gear, tape measures, safety gear, and any other tools needed.

Mark the bend point:

Use a tape measure to determine the desired bend point on the light pole. This is where the bend comes in. Mark this clearly.

Prepare the bending equipment:

Set up the hydraulic bending machine according to the manufacturer's instructions. Make sure it is firmly in place and stable.

Secure the light pole:

Use clamps or other means to secure the light pole in place, ensuring the light pole is properly supported and does not move during bending.

Bending the light pole:

Engage the hydraulic bending machine and slowly apply pressure to begin bending the light pole at the marked bending point. Follow the manufacturer's instructions for the specific machine you are using. Pressure must be applied gradually and evenly to avoid damaging the pole.

Monitor the bending:

As the bending process continues, keep an eye on the progress. Use leveling devices to ensure even and accurate bending.

Check the final bend:

Once the desired bend is achieved, use a tape measure and/or level to confirm that the rod bends as required. If the bend is not accurate, make the necessary adjustments.

Secure the rod:

After bending, remove the clips or other supports holding the rod in place. Double check that the pole is stable and installed in the correct position.

Install a light pole:

Install a curved street light pole according to the manufacturer's instructions, making sure it is securely fastened and connected to the relevant power or utility line. It is important to note that bending light poles can only be done by trained professionals with the necessary experience and expertise. Always follow safety protocols and guidelines and comply with any local regulations or codes that apply to the job.

Customization

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

In our company, we pride ourselves on being an established manufacturing facility. Our state-of-the-art factory has the latest machinery and equipment to ensure that we can provide our customers with the highest quality products. Drawing on years of industry expertise, we continually strive to deliver excellence and customer satisfaction.

2. Q: What's your main product?

A: Our main products are Solar Street Lights, Poles, LED Street Lights, Garden Lights and other customized products etc.

3. Q: How long is your lead time?

A: 5-7 working days for samples; around 15 working days for bulk order.

4. Q: What's your shipping way?

A: By air or sea ship are available.

5. Q: Do you have OEM/ODM service?

A: Yes.

Whether you are looking for custom orders, off-the-shelf products or custom solutions, we offer a wide range of products to meet your unique needs. From prototyping to series production, we handle every step of the manufacturing process in-house, ensuring we can maintain the highest standards of quality and consistency.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top