Hot-DIP Outdoor Single Arm LED Street Light Pole

DOWNLOAD

RESOURCES

Description

Hot DIP Outdoor Single Arm LED Street Light Pole will undergo anti-corrosion treatment on the surface and inside and outside of the pole body after the pole is rolled and welded. The surface will be covered with a corrosion-resistant zinc layer to prevent rusting of the steel. Hot dip galvanizing is a method of anti-corrosion treatment for steel. The hot-dip galvanizing process involves immersing the processed street lamp poles, which have been degreased, pickled, impregnated, and dried, in a molten zinc solution at around 500 ℃ to attach a zinc layer to the surface of the steel parts, thus providing anti-corrosion protection. The thickness of the galvanized layer is usually above 75 μ m, making the lamp poles corrosion-resistant for more than 30 years.

Technical Data

| Product Name | Hot-DIP Outdoor Single Arm LED Street Light Pole | ||||||

| Material | Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 | ||||||

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | ||||||

| Minimum yield strength | 285Mpa | ||||||

| Max ultimate tensile strength | 415Mpa | ||||||

| Anti-corrosion performance | Class II | ||||||

| Against earthquake grade | 10 | ||||||

| Color | Customized | ||||||

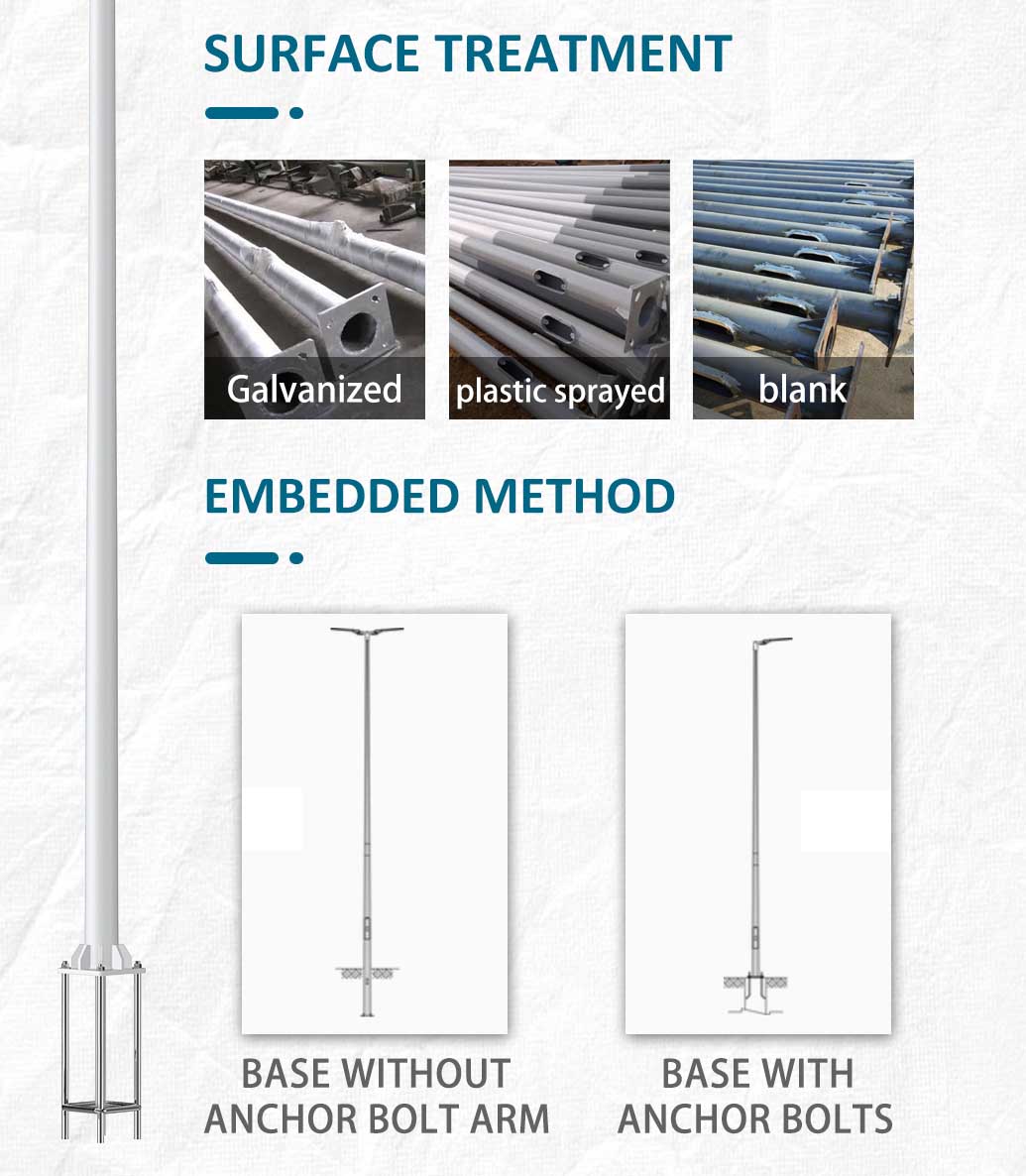

| Surface treatment | Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II | ||||||

| Shape Type | Conical pole, Octagonal pole,Square pole, Diameter pole | ||||||

| Arm Type | Customized: single arm,double arms,triple arms,four arms | ||||||

| Stiffener | With big size to strength the pole to resist the wind | ||||||

| Powder coating | Thickness of powder coating is 60-100um. Pure polyester plastic powder coating is stable, and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). | ||||||

| Wind Resistance | According to local weather condition, General design strength of wind resistance is ≥150KM/H | ||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | ||||||

| Hot-Dip Galvanized | Thickness of hot-galvanized is 60-100um. Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of pole is more than 25 years, and the galvanized surface is smooth and with the same color. Flake peeling hasn't been seen after maul test. | ||||||

| Anchor bolts | Optional | ||||||

| Material | Aluminium,SS304 is available | ||||||

| Passivation | Available | ||||||

Manufacturing Process

Project Presentation

Our Exhibition

Our Certifications

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top