Double Arm 30ft Aluminum Light Pole

DOWNLOAD

RESOURCES

Technical Data

| Height | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | ||||||

| Minimum yield strength | 285Mpa | ||||||

| Max ultimate tensile strength | 415Mpa | ||||||

| Anti-corrosion performance | Class II | ||||||

| Against earthquake grade | 10 | ||||||

| Color | Customized | ||||||

| Shape Type | Conical pole, Octagonal pole, Square pole, Diameter pole | ||||||

| Arm Type | Customized: single arm, double arms, triple arms, four arms | ||||||

| Stiffener | With a big size to strengthen the pole to resist the wind | ||||||

| Powder coating | Thickness of powder coating is 60-100um. Pure polyester plastic powder coating is stable and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). | ||||||

| Wind Resistance | According to local weather conditions, general design strength of wind resistance is ≥150KM/H | ||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | ||||||

| Anchor bolts | Optional | ||||||

| Material | Aluminium | ||||||

| Passivation | Available | ||||||

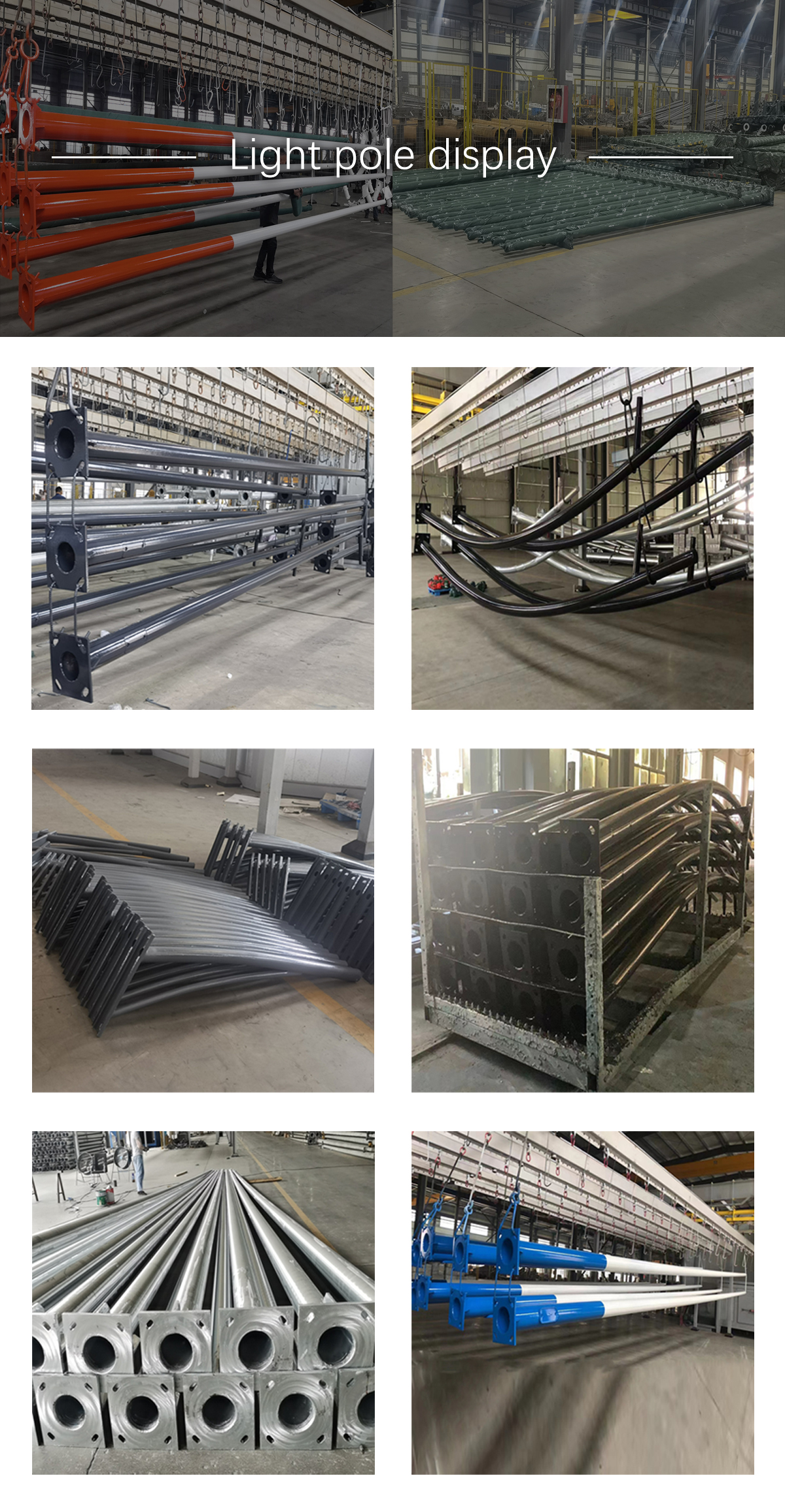

Product Show

Customization

Forging process

Cast aluminum outdoor post lights are made using the forging process, a technique that has been used for centuries to shape metal into various shapes. The process involves heating aluminum to a specific temperature and then applying enormous pressure to shape it into the desired design. The forged aluminum is then slowly cooled to enhance its strength and durability.

The forging process of cast aluminum outdoor post lights begins with the melting of the aluminum, which is then poured into molds to form the desired shape. Aluminum is heated to temperatures in excess of 1000 degrees Fahrenheit, at which point it melts and can be easily shaped. The molten aluminum is then poured into molds and allowed to cool.

During cooling, the aluminum solidifies and takes on the shape of the mold. This is where the strength of cast aluminum post lights comes from. The slow cooling process causes the aluminum to form a crystalline structure, which gives it exceptional strength. This ensures that the lights can withstand harsh weather conditions including rain, snow, and extreme temperatures.

Once the aluminum has cooled and solidified, it is removed from the mold and undergoes a series of finishing processes to enhance its appearance. These may include grinding, polishing, and painting to achieve the desired finish. Cast aluminum outdoor post lights can have either a smooth or textured finish, depending on the manufacturer's design and style preferences.

One of the main advantages of cast aluminum outdoor post lights is their portability. The forging process allows aluminum to be shaped into intricate designs while maintaining a lightweight structure. This makes it easier to install and reposition lights as needed. Although the cast aluminum post light is lightweight, it is very strong due to the forging process that enhances its strength.

Another benefit of the forging process is the ability to produce intricate and detailed designs. Cast aluminum outdoor post lights can be manufactured in a variety of designs, shapes, and sizes to suit different outdoor spaces and architectural styles. Whether you prefer a modern, minimal design or a more ornate, traditional look, there is a cast aluminum post light to suit your preferences.

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

In our company, we pride ourselves on being an established manufacturing facility. Our state-of-the-art factory has the latest machinery and equipment to ensure that we can provide our customers with the highest quality products. Drawing on years of industry expertise, we continually strive to deliver excellence and customer satisfaction.

2. Q: What's your main product?

A: Our main products are Solar Street Lights, Poles, LED Street Lights, Garden Lights and other customized products etc.

3. Q: How long is your lead time?

A: 5-7 working days for samples; around 15 working days for bulk order.

4. Q: What's your shipping way?

A: By air or sea ship are available.

5. Q: Do you have OEM/ODM service?

A: Yes.

Whether you are looking for custom orders, off-the-shelf products or custom solutions, we offer a wide range of products to meet your unique needs. From prototyping to series production, we handle every step of the manufacturing process in-house, ensuring we can maintain the highest standards of quality and consistency.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top