4-12M Single Arm Conical Round Light Pole

DOWNLOAD

RESOURCES

Technical Data

| Material | Commonly Q345B/A572, Q235B/A36, Q460 ,ASTM573 GR65, GR50 ,SS400, SS490, ST52 | |||||||

| Height | 4M | 5M | 6M | 7M | 8M | 9M | 10M | 12M |

| Dimensions(d/D) | 60mm/140mm | 60mm/150mm | 70mm/150mm | 70mm/170mm | 80mm/180mm | 80mm/190mm | 85mm/200mm | 90mm/210mm |

| Thickness | 3.0mm | 3.0mm | 3.0mm | 3.0mm | 3.5mm | 3.75mm | 4.0mm | 4.5mm |

| Flange | 260mm*12mm | 260mm*14mm | 280mm*16mm | 300mm*16mm | 320mm*18mm | 350mm*18mm | 400mm*20mm | 450mm*20mm |

| Tolerance of dimension | ±2/% | |||||||

| Minimum yield strength | 285Mpa | |||||||

| Max ultimate tensile strength | 415Mpa | |||||||

| Anti-corrosion performance | Class II | |||||||

| Against earthquake grade | 10 | |||||||

| Color | Customized | |||||||

| Surface treatment | Hot-dip Galvanized and Electrostatic Spraying, Rust Proof, Anti-corrosion performance Class II | |||||||

| Shape Type | Conical pole, Octagonal pole,Square pole, Diameter pole | |||||||

| Arm Type | Customized: single arm,double arms,triple arms,four arms | |||||||

| Stiffener | With big size to strength the pole to resist the wind | |||||||

| Powder coating | Thickness of powder coating is 60-100um. Pure polyester plastic powder coating is stable, and with strong adhesion & strong ultraviolet ray resistance. The surface is not peeling even with blade scratch (15×6 mm square). | |||||||

| Wind Resistance | According to local weather condition, General design strength of wind resistance is ≥150KM/H | |||||||

| Welding Standard | No crack, no leakage welding, no bite edge, weld smooth level off without the concavo-convex fluctuation or any welding defects. | |||||||

| Hot-Dip Galvanized | Thickness of hot-galvanized is 60-100um. Hot Dip Inside and outside surface anti-corrosion treatment by hot dipping acid. which is in accord with BS EN ISO1461 or GB/T13912-92 standard. Designed life of pole is more than 25 years, and the galvanized surface is smooth and with the same color. Flake peeling hasn't been seen after maul test. | |||||||

| Anchor bolts | Optional | |||||||

| Passivation | Available | |||||||

Product Description

Conical street light pole is made from high-quality materials and perfected by a sophisticated production process, the product promises to stand the test of time while brightly illuminating streets, roads, and highways.

The production process of the conical street light pole is meticulous and thorough. Each rod is made using state-of-the-art technology and advanced machinery, ensuring precision and consistency in every detail. High-quality materials are selected first, then the rod is shaped into a conical structure to optimize its strength and longevity. The poles are carefully welded and undergo a strict quality control process to guarantee their performance and durability.

In addition, the conical street light poles are designed to withstand harsh weather conditions. Whether it's harsh sun, heavy rain, or strong wind, these poles can take it. With a corrosion-resistant coating, they maintain their pristine appearance, ensuring long-lasting, reliable lighting.

One of the main features of tapered light poles is their flexible installation options. Suitable for a variety of spaces, these light poles can be easily installed on streets, roads, highways, or any urban area where efficient lighting is required. The tapered design provides optimal light distribution, illuminating large areas while minimizing light pollution. This ensures safety and convenience for pedestrians and motorists, enhancing the overall urban experience.

These conical street light poles not only provide excellent lighting but are also very energy efficient. They are specially designed to adapt to various lighting technologies such as LED or solar lights, which can significantly reduce energy consumption and environmental impact. By adopting environmentally friendly lighting solutions, cities can contribute to a more sustainable future while benefiting from reduced energy costs.

In addition, the maintenance of the conical street light pole is also very convenient. The materials used and careful construction ensure minimal wear over time, resulting in fewer replacements and repairs. These poles provide municipalities and councils with significant cost savings by reducing the need for frequent maintenance.

Customization

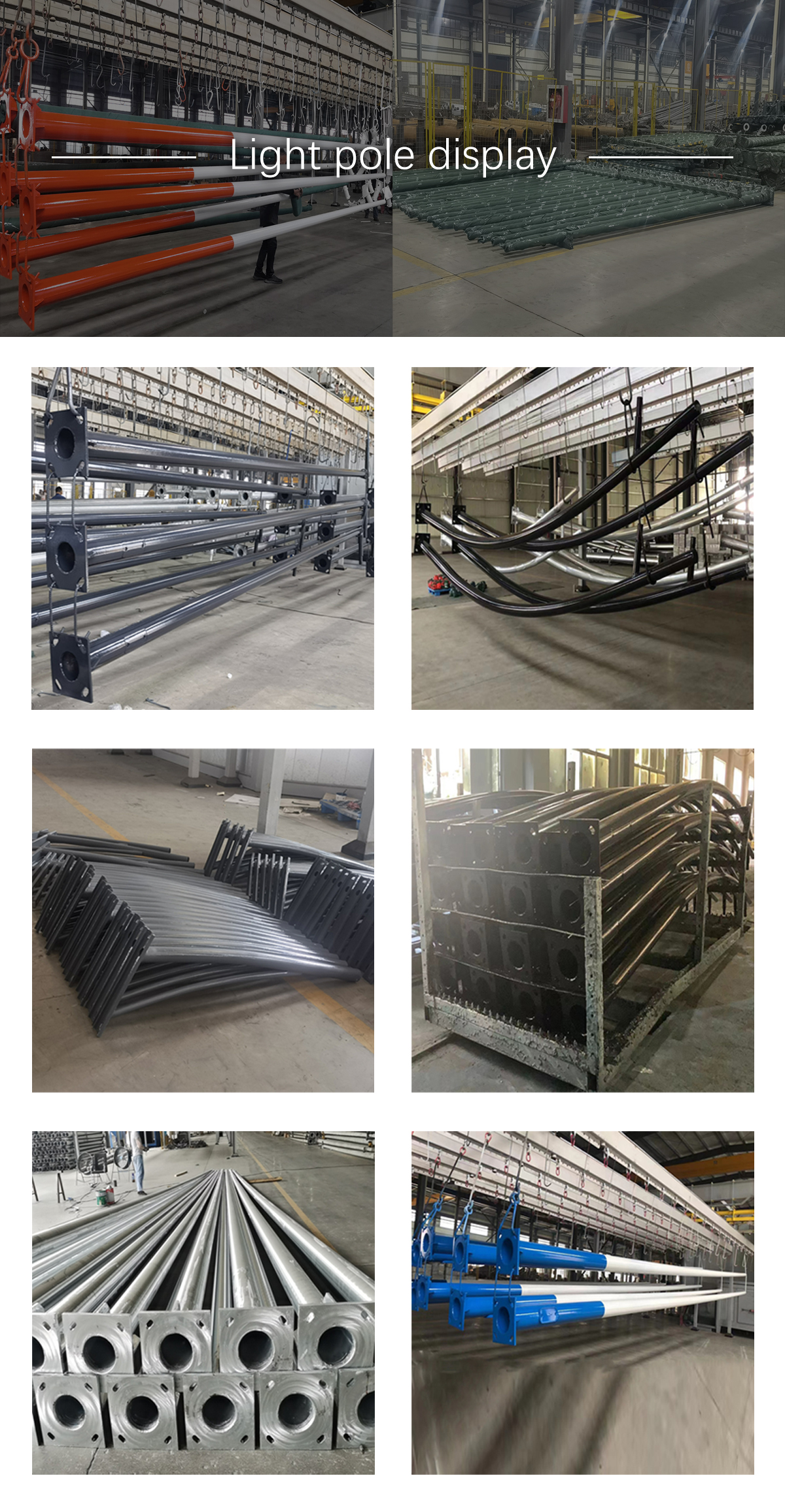

Product Show

FAQ

1. Q: Are you a factory or trading company?

A: We are a factory.

In our company, we pride ourselves on being an established manufacturing facility. Our state-of-the-art factory has the latest machinery and equipment to ensure that we can provide our customers with the highest quality products. Drawing on years of industry expertise, we continually strive to deliver excellence and customer satisfaction.

2. Q: What's your main product?

A: Our main products are Solar Street Lights, Poles, LED Street Lights, Garden Lights and other customized products etc.

3. Q: How long is your lead time?

A: 5-7 working days for samples; around 15 working days for bulk order.

4. Q: What's your shipping way?

A: By air or sea ship are available.

5. Q: Do you have OEM/ODM service?

A: Yes.

Whether you are looking for custom orders, off-the-shelf products or custom solutions, we offer a wide range of products to meet your unique needs. From prototyping to series production, we handle every step of the manufacturing process in-house, ensuring we can maintain the highest standards of quality and consistency.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top